The manufacturing and delivery of the blowing trailing edge module of the aerofoil section to be tested at VKI (Von Karman Institute) wind tunnel facility has been successfully accomplished.

MOTHIF project is increasing pace!

We are almost on the starting line, which will be February next year, for the wind tunnel test campaign at VKI.

And what a journey it has been!

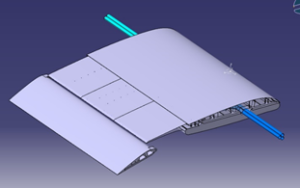

MOTHIF project aims to demonstrate feasibility of a new high lift device generation paradigm: blowing trailing edge.

The blowing jet spreads out from the main aerofoil trailing edge and it will directly influence both the main aerofoil and flap boundary layers.

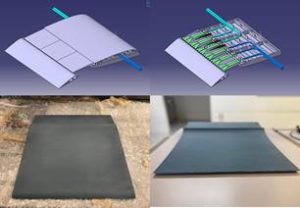

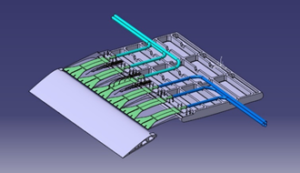

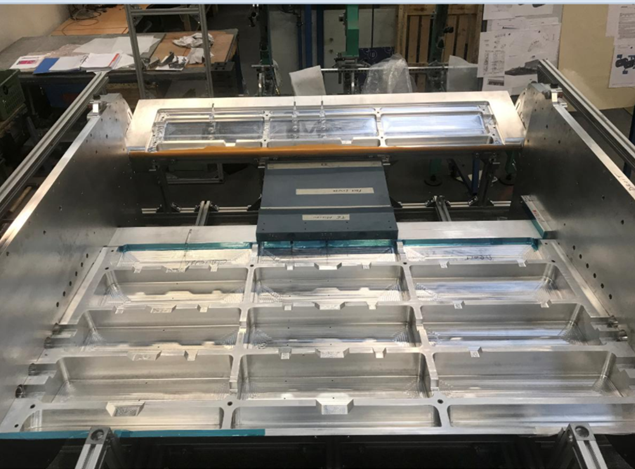

Representative bi-dimensional tests on the subsonic wind tunnel facility at VKI will demonstrate the mutual interference, the main influencing parameter (as gap and pressure), the results and also the flow features, thanks to an innovative PIV (Particle Image Velocimetry) technique and other flow visualizations. Thanks to our partners SONACA and Von Karman Institute we started from the white paper, by designing the particular aerofoil and flap, optimizing flap’s overlap and gap positions, improving the trailing edge internal routing for blowing and taking care of the space on the main aerofoil for the pressure pipes.

Then we moved forward on the manufacturing.

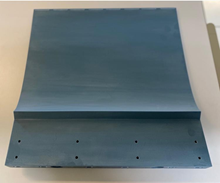

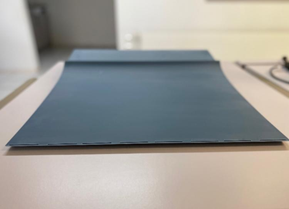

Piaggio has been in charge for the trailing edge part and, together with its supplier 3D Systems, we promoted SLS (laser stereolithografy additive manufacturing): the trailing edge part has been divided in three pieces, fully integrated with the pressure taps and duct routings, manufactured with the best precision and the higher finish quality.

On the 20th of October, our partner SONACA has received all the parts and it is now in charge of the final assembly on the complete wind tunnel specimen.

Pandemic makes it trickier but… we never stop innovating!

Stay tuned for the next updates.