Piaggio Aerospace has completed the final testing campaign for the innovative composite wing developed under the European co-funded research project Clean Aviation (OPTICOMS project)

A composite wingbox, an integral 7-meter “fasteners free” architecture using primary bonding for assembly, has been designed and manufactured by Israel Aerospace Industries in collaboration with DANOBATGROUP, Coriolis Composites, and Techni-Modul Engineering.

The bonding assembly has been monitored with an innovative Structural Health Monitoring (SHM) system developed by CIRA – Centro Italiano Ricerche Aerospaziali.

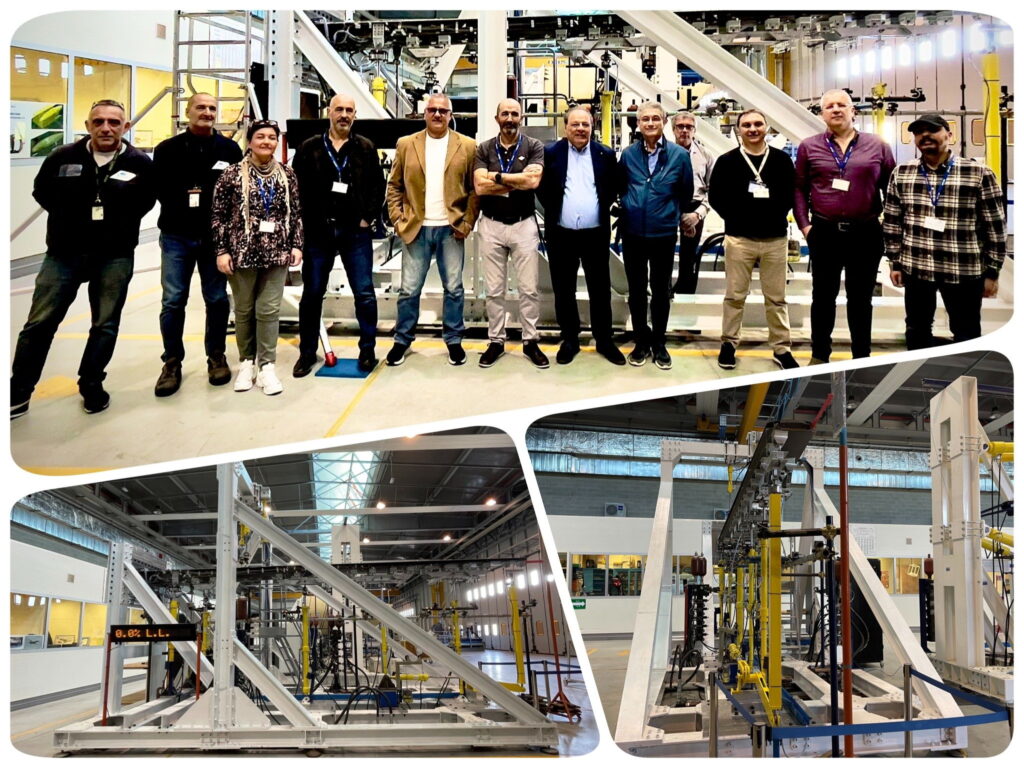

A static test has been carried out at Piaggio Aerospace’s labs in Villanova d’Albenga, where the test rig was implemented to simulate the operational loading conditions of the wing.

The test demonstrated the full capability of the wing to withstand the static loads and the maturity level of the SHM system. This underscores Piaggio Aerospace’s commitment in the field of highly efficient composite structures, with the objective of enabling small aircraft companies to justify building up automation infrastructure and realize a return on investment on low volume production.